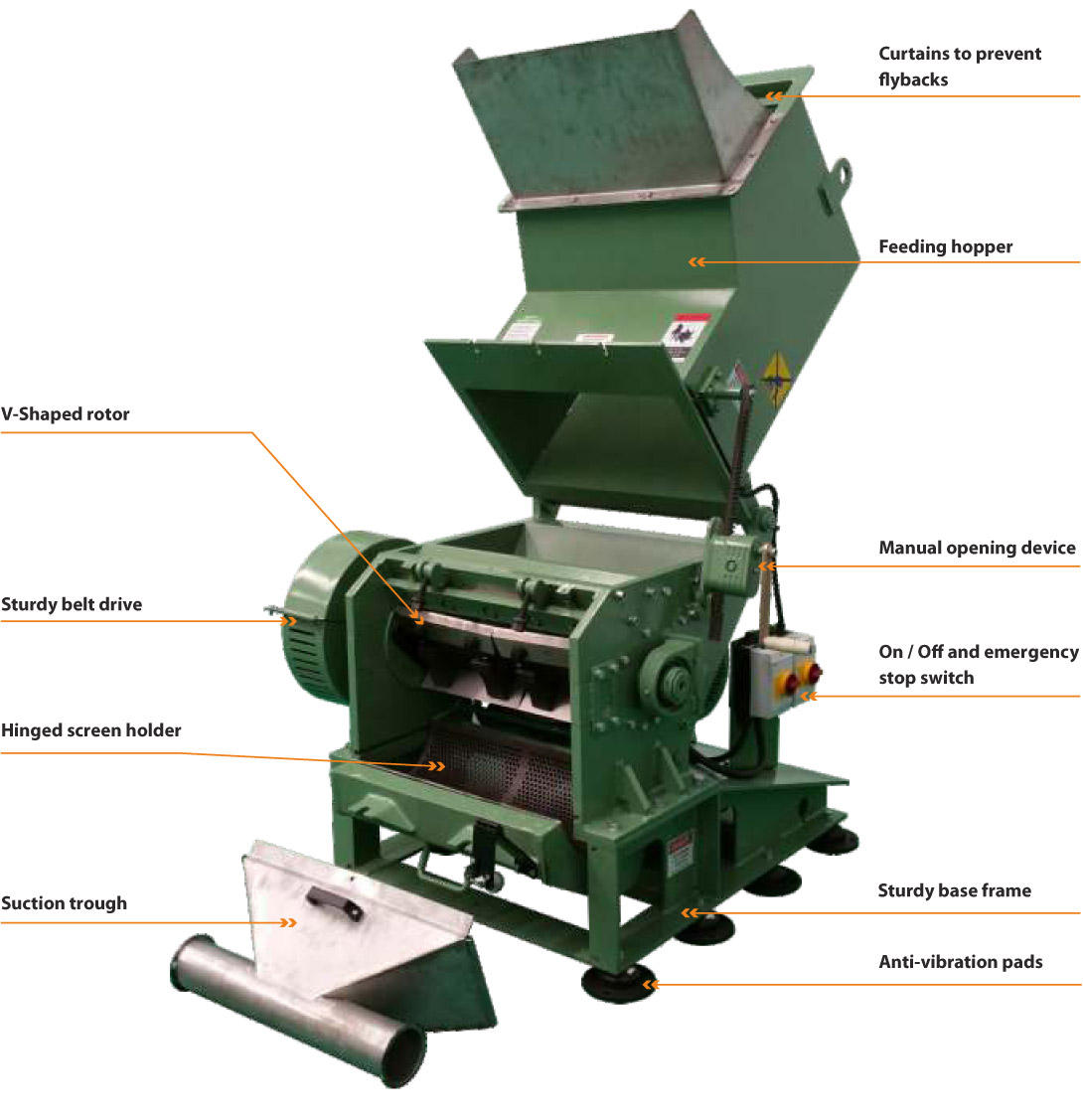

APPLICATIONS

The compact granulators of the G and H series are primarily designed for use in injection and blow moulding applications to recycle voluminous parts such as bottles, canisters and crates, as well as blow moulding flush and injection sprues. The low height makes them ideally suitable for the manual feeding of such parts. The low noise level and small footprint makes them the perfect fit for inline recycling operations.

GENERAL DESCRIPTION

The economical granulators of the G and H series are available in two rotor diameters, 250 and 400 mm with widths ranging from 300 to 1000 mm. The G series features an open F rotor while the H series relies on a heavier S rotor. The curved and highly tangential backwall of the cutting chamber ensures an aggressive ingestion while also avoiding blockages. The rigid design makes them dependable units and includes advanced standard features such as replaceable wear plates. The rotor and stator knives are adjusted outside of the machine to reduce downtime for maintenance.

ADVANTAGES

- Compact design, small footprint

- All knives are adjusted outside of the machine in a jig to reduce downtime for maintenance

- Aggressive infeed due to curved backwall of the cutting chamber

- Large screen area for high throughput rates

- Modern V-cut technology creates a high-quality regrind while reducing energy consumption and noise

Open Granulator: Stator knives,

Open Granulator: Stator knives,Rotor knives, Screen

Granulator: Sound-proofed version

Granulator: Sound-proofed version